Welcome to A. Pepper Designs, where we specialize in tailor-made display solutions for eyewear companies and retailers. With a turn-key approach and 28 years of specialized experience, we ensure your display projects are completed efficiently and effectively. Our expertise encompasses over 30 unique, injection molded components, enabling us to both enhance our standard display offerings and tackle custom challenges presented by our clients. Our design process is streamlined to be risk-free for repeat customers who benefit annually from our innovative displays. Having served the industry for nearly three decades, we understand the nuances that drive growth and success in the eyewear market. Let us help you turn your vision into reality with displays that are not only functional but also visually captivating. Below are the detailed 6 steps to creating your new displays with A. Pepper Designs.

Design Consultation

Concept Generation

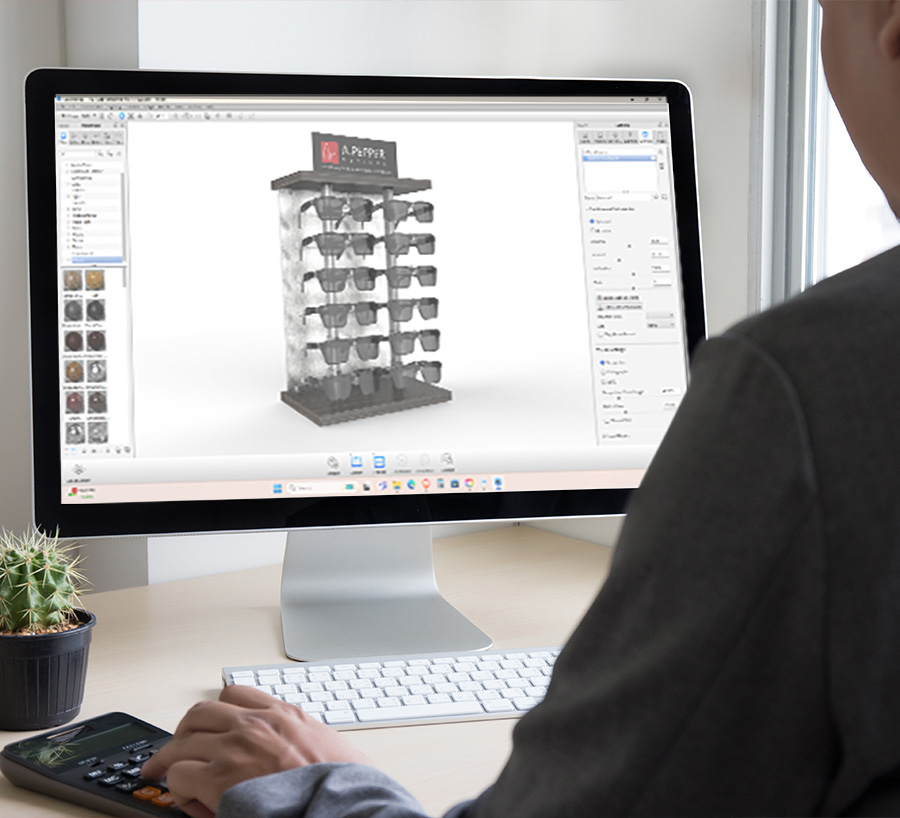

Virtual 3D Rendering

Cost Estimate and Engineering

With the client’s approval of the final designs, a comprehensive cost breakdown is prepared. Concurrently, our engineers begin the intricate process of transforming these designs into functional products. This stage is crucial for detailing the technical specifications and preparing for the prototyping phase.

Prototyping

Production/Manufacturing

The final stage involves scaling the approved prototype for mass production. Utilizing our advanced manufacturing facilities in Pittsburgh, we leverage cutting-edge engineering and production techniques to deliver high-quality, consistently manufactured outcomes at scale.